Why is a polyamide thermal break important in aluminum windows?

In recent years, the construction industry has faced growing demands for energy efficiency, thermal performance, and sustainable architecture. Among the most effective solutions for meeting these challenges are thermal break aluminum systems—powered by specialized polyamide strips that separate the interior and exterior faces of the window frame.

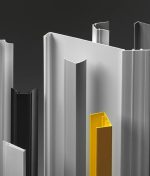

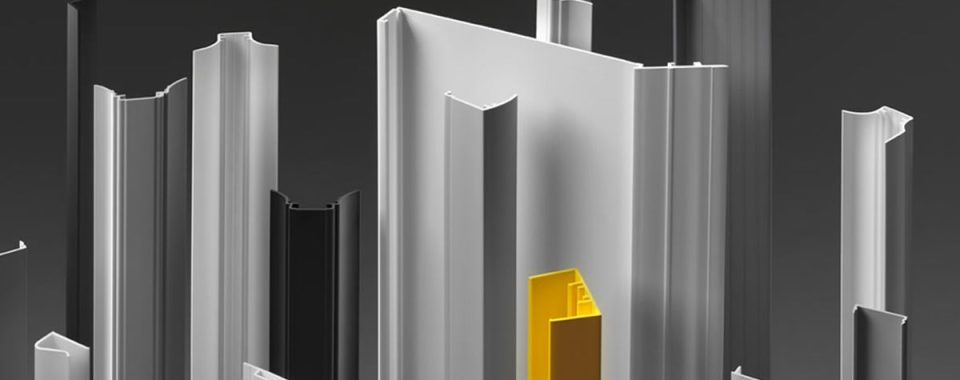

Polyamide thermal breaks are reinforced with glass fibers, offering superior thermal resistance, high mechanical strength, and long-term durability. These profiles significantly reduce thermal bridging, prevent condensation, and enhance both thermal and acoustic comfort inside buildings, making them ideal for modern aluminum fenestration systems.

From an SEO perspective, keywords such as “polyamide thermal break”, “Aluminum window insulation”, “Glass fiber reinforced polyamide”, and “Thermal barrier strips” are essential for attracting architects, engineers, and building professionals to your website. Optimized content with relevant search terms ensures better visibility and engagement in organic search.

As the first domestic producer of thermal break strips in Iran, Nurlu Plast leads the market with its proprietary formulations, precision extrusion lines, and internationally compliant quality standards. Our polyamide profiles deliver smooth surfaces, dimensional accuracy, and exceptional consistency—tailored to meet the needs of facade contractors and aluminum profile manufacturers.

Choosing the right thermal break solution is not just a technical decision—it’s a strategic investment in building performance, energy savings, and user comfort. Nurlu Plast stands at the forefront of engineering excellence in polyamide extrusion for high-performance window and curtain wall applications.