Comparison of Polyamide (PA) and Rigid PVC in Industrial and Construction Applications

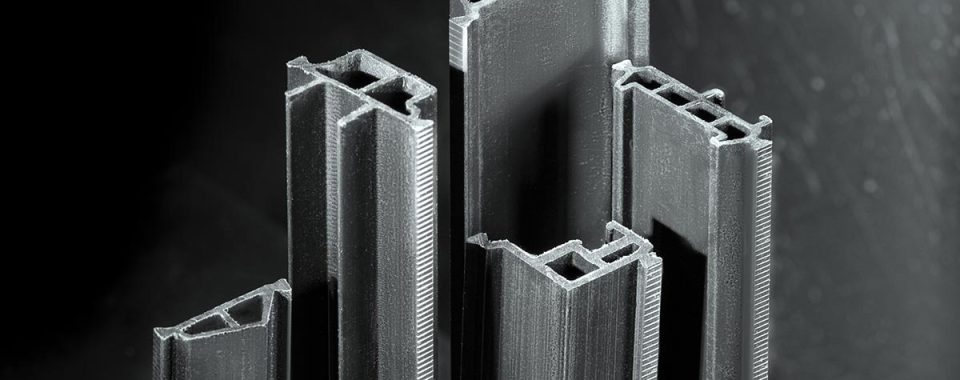

In both construction and industrial sectors, choosing the right material for extruded profiles is crucial to ensure long-term performance, durability, and efficiency. Among the widely used materials, Polyamide (PA) and Rigid Polyvinyl Chloride (PVC) stand out as two primary options for technical applications. Despite similarities in extrusion processing, these materials differ significantly in mechanical behavior, environmental stability, and sustainability.

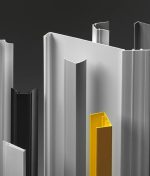

Mechanically, polyamide—especially when reinforced with glass fibers—exhibits superior resistance to stress, impact, and wear. It performs exceptionally well in thermal environments and is widely used in aluminum thermal break systems to reduce heat transfer and improve energy efficiency. Rigid PVC, while mechanically sound for many applications, tends to deform under prolonged stress or high temperatures, making it less suitable for load-bearing or high-heat conditions.

From an environmental exposure perspective, polyamide provides strong resistance to moisture, chemicals, and UV radiation, making it ideal for outdoor or industrial applications. Rigid PVC, on the other hand, is more vulnerable to UV degradation and may require additional stabilizers for long-term sun exposure. It is best used in semi-protected environments.

Environmentally, polyamide offers a more sustainable profile due to its longevity, reusability, and higher recyclability. In contrast, rigid PVC contains chlorine and poses recycling challenges, which has led to increased restrictions in several countries. As a result, many sectors are shifting toward greener alternatives such as polyamides.

Economically, rigid PVC remains a cost-effective choice for many basic applications. However, for projects demanding dimensional precision, long-term stability, and high-performance material behavior, the higher upfront cost of polyamide is often offset by lower maintenance and longer service life.

Ultimately, selecting between polyamide and rigid PVC should depend on the application’s technical requirements, environmental conditions, and sustainability goals. Nurlu Plast offers expert guidance and a complete range of profiles in both materials—helping clients make informed and optimized material choices.