About Us

Nurlu Green — because “being good is not enough.”

By engineering thermal-break profiles and precise sealing, we help reduce energy loss in buildings. Inside the factory, we take responsible manufacturing, waste management, and green training seriously.

Nurlu Plast

Sustainability & Environment at Nurlu Plast

From energy-efficient product design to responsible manufacturing — our commitment to the planet

– Product Impact on Energy Savings

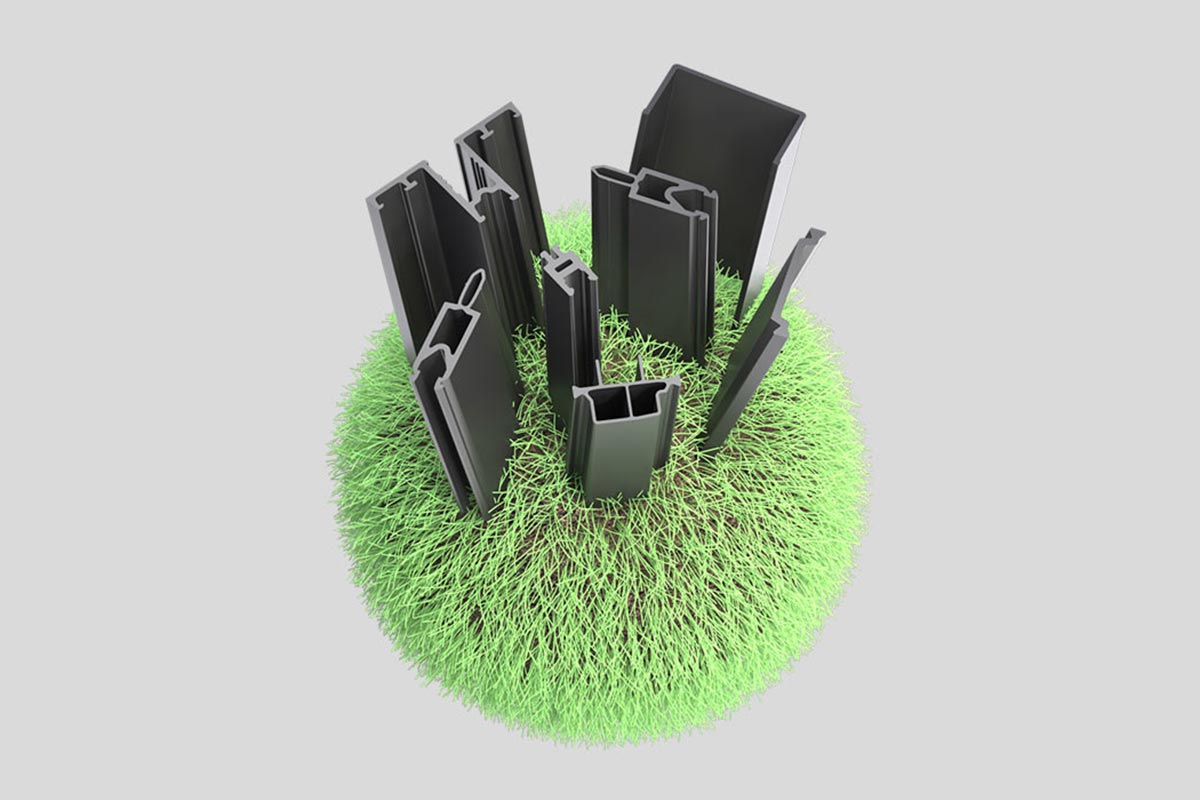

- Polyamide Thermal-Break Profiles: Reduce heat transfer in aluminium systems and improve door/window energy performance.

- EPDM Gaskets: Durable air- and water-sealing to cut air leakage and prevent energy waste.

- Engineered R-PVC: High durability and longer service life — fewer replacements, less waste.

Methodology note: We estimate energy savings via improved window/façade U-Value and reduced air leakage, then convert to annual kWh savings and CO₂e equivalents (sample report in preparation).

– Responsible Manufacturing in Our Plant

- Material & Waste Management: Sorting and recycling of production scrap; controlled re-granulation where applicable.

- Optimised Energy Use: Line-level electricity monitoring, idle-mode shutdowns, and preventive maintenance.

- Low-odour/Low-VOC Formulations: (selected recipes) with emissions control.

- Safety & Training: HSE procedures, periodic trainings, and continuous monitoring.

– Green Culture

- “No single-use cups” campaigns, office waste sorting at source, and periodic green performance reviews by unit.

- Employee suggestion scheme with recognition for ideas that reduce consumption or scrap.

– Standards & Compliance

- Progress toward ISO 14001 (environmental management) and continuous alignment with relevant requirements (e.g., RoHS/REACH where applicable).

- Raw-material traceability and documentation for supply-chain transparency.

– Goals & KPIs

- Reduce energy-intensity (kWh per kg of product) by 3.5% by end of 2026.

- Increase recycling rate of production scrap to 17%.

- Cut process water consumption per tonne of product by 10%.

- Publish the Nurlu Sustainability Report annually.